Three different Michigan State University departments are working together in sustainable practices to convert campus waste into energy.

In 2008, MSU established the Anaerobic Digestion Research and Education Center (ADREC), which turns animal and culinary waste into power for the campus. MSU Culinary Services and MSU Dairy Cattle Teaching and Research Center contribute different kinds of waste to sustainably convert it.

MSU professor and the director of the ADREC Wei Liao said anaerobic digestion is a biological process in which bacteria convert organic matter into methane and carbon dioxide.

The gasses generated from the process is converted into energy and used in the MSU power grid. He said there are two digesters on the south side of campus. They are used for research purposes as well as contributing power to campus. Liao said they use it to study microbiology and engineering processes.

Liao said the energy created can power around 10 campus buildings.

According to MSU’s sustainability website, MSU is one of three universities in the U.S. with a "self-sustaining" anaerobic digester.

All of the waste comes from two different sources: the MSU Dairy Farm and Brody dining hall. Student Life and Engagement sustainability officer Carla Iansiti said Brody has a trough in the back of the kitchen where food waste is put.

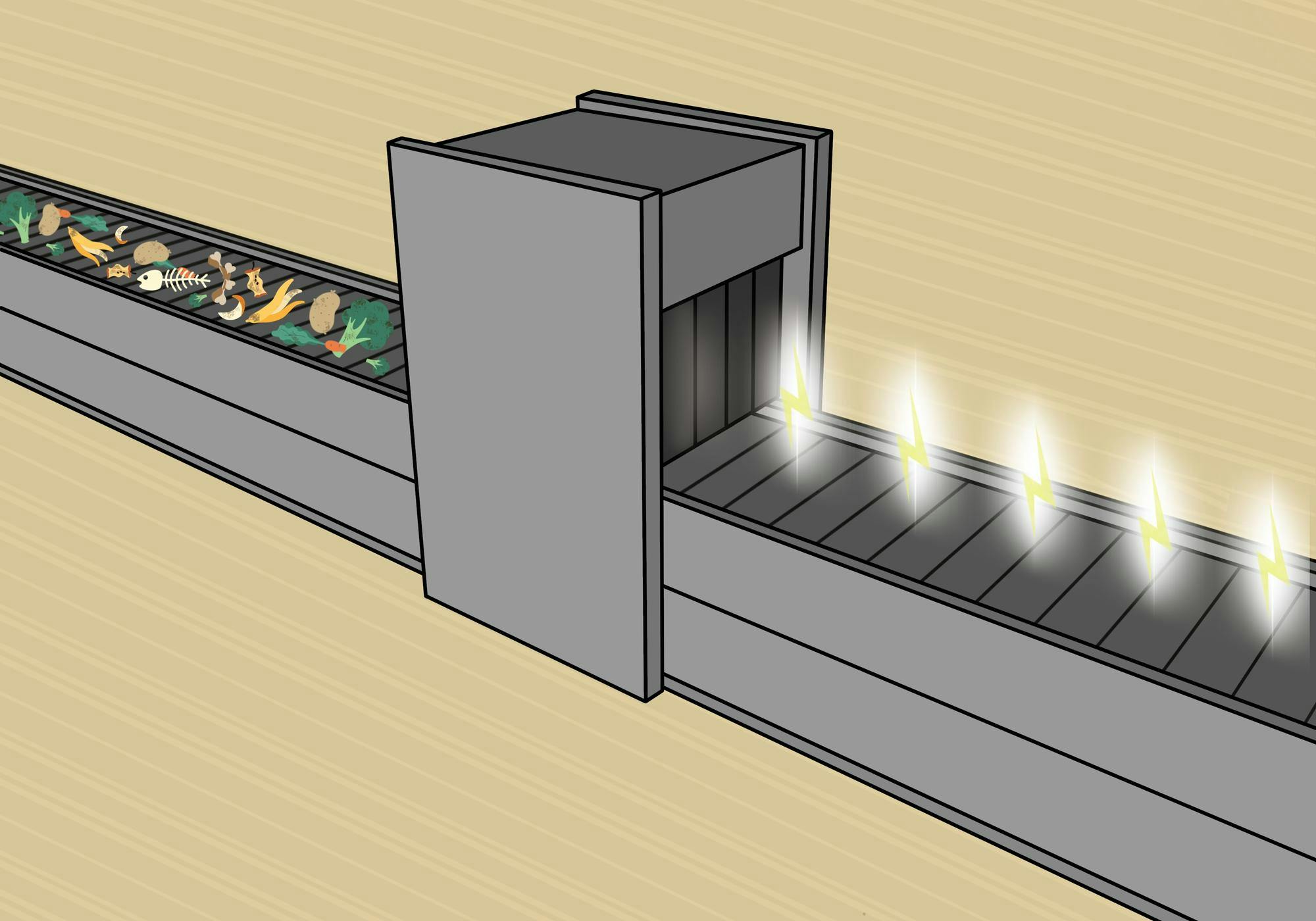

When food is discarded, it is placed in the trough with water, which then goes through a pulper, a machine that breaks down food into smaller pieces.

"It's kind of like a washing machine, where you add water, chops it up, and then it's sent downstairs, and the water is extracted back out, leaving kind of a wet sawdust type product," Iansiti said. "It goes into a container, and we deliver it to the digester twice a week."

Brody is the only dining hall with a pulper that allows for this process. Iansiti said if they installed a pulper in other dining halls, they would not have a way to transport that extra waste to the digester.

She said there is no plan of installing a pulper in other cafeterias due to each dining hall’s unique design. However, food scraps do not go to waste, and are used for other sustainability programs.

"Right now, we have post consumer programs happening in all the halls," Iansiti said. "Vegetable scraps are going to vermicomposting, and we also have some going to Hammond farms. So we have programs happening all over."

The properties of the food waste is how the digester turns the product into methane.

"In food waste, we have carbohydrates, proteins and fats, those are all the good nutrients for that group of anaerobic microbes," Liao said.

Waste from the farm arrives at the digester more often than the food waste. Manager at the MSU Dairy Cattle Teaching and Research Center Jim Good said they transport manure from the farm twice a day.

"The combination of the food waste along with the cattle manure makes a unique blend of methane that has a very good use for running through a generator, producing electricity," Good said. "So our main focus, is that we produce the manure with our 250 mature cows that goes back daily to the digester."

Good said every transport is 1,500 gallons of manure. The farm also has an underground pump, which transports around 9,000 gallons of manure in one day, totaling 12,000 gallons of waste from the farm daily.

According to MSU’s sustainability website, operators add 20,000 gallons of waste to the digester every day, where microorganisms break down the waste in the holding tank for 20-30 days.

"The benefit we would get is that we're able to utilize the methane from the cow manure, where that just doesn't get lost up into the environment," Good said. "We're able to utilize that, we capture that gas, we run that methane through a generator and the generator produces electricity."

Good said manure does not disappear after the process. According to MSU’s sustainability website, the ending byproducts after the material is broken down are liquid and solid fertilizers.

Support student media!

Please consider donating to The State News and help fund the future of journalism.

Liao said they may run into problems with contamination within the anaerobic digester.

"Oftentimes we see trash, meaning there's some latex gloves, plastic bags and even some bottles," Liao said. "And when those things mix with the food waste, dumping the digester is troublesome, because the plastic trash are not biodegradable."

To reduce other contaminants at the source, Iansiti said the machine at Brody has magnets on the side to pull any metal materials mixed in with the food waste out of the system’s flow.

Liao said this is part of the campus's sustainability practices. He said that they are trying to eliminate landfill dumping.

"It's got two functions to it too," Good said. "We're producing a value-added product coming off to the farm that would be considered a waste product. So there's one, and we're helping the environment out too. So you've got two big win-win benefits."

Discussion

Share and discuss “MSU facilities work together to turn waste into power” on social media.